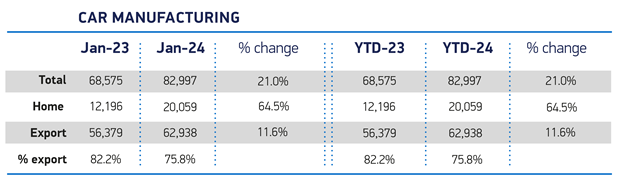

UK car production got off to a fast start in January, according to the latest figures published by the Society of Motor Manufacturers and Traders (SMMT). Volumes rose 21.0% to 82,997 units, marking the best January performance since 2021 and the fifth straight month of growth as global demand .

The SMMT said demand for British-built brands continued to grow and legacy supply chain challenges, notably semiconductor shortages, abated further.

The bulk of UK car output was for export (75.8%), with overseas shipments up 11.6% to 62,938 units – a rise of 6,559. However, output for the domestic market commanded the biggest volume growth, up by an additional 7,863 units (+64.5%). The EU was the largest global market for British-built cars, taking more than half (53.2%) of exports, followed by the US (15.0%), China (10.5%), Japan (2.8%) and Australia (2.3%). Shipments to the EU, US and China all rose, by 5.0%, 81.1% and 33.2% respectively.

UK production of battery electric (BEV), plug-in hybrid (PHEV) and hybrid (HEV) vehicles rose again by a combined 4.5% to 29,590 units to account for 35.7% of overall output. In line with overall figures, the majority of these models were exported.

Mike Hawes, SMMT Chief Executive, said: “A positive start to the year for UK car production bodes well for the industry and the many thousands of livelihoods on which it depends. There can be no room for complacency, however, given economic headwinds and geopolitical tensions. There must be a relentless commitment to competitiveness, building on the significant recent investments into the sector. The forthcoming Budget is a chance for Government to do just that by introducing measures to boost UK automotive manufacturing, focused on energy, investment competitiveness and market demand.”

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataStructural issues for UK auto industry

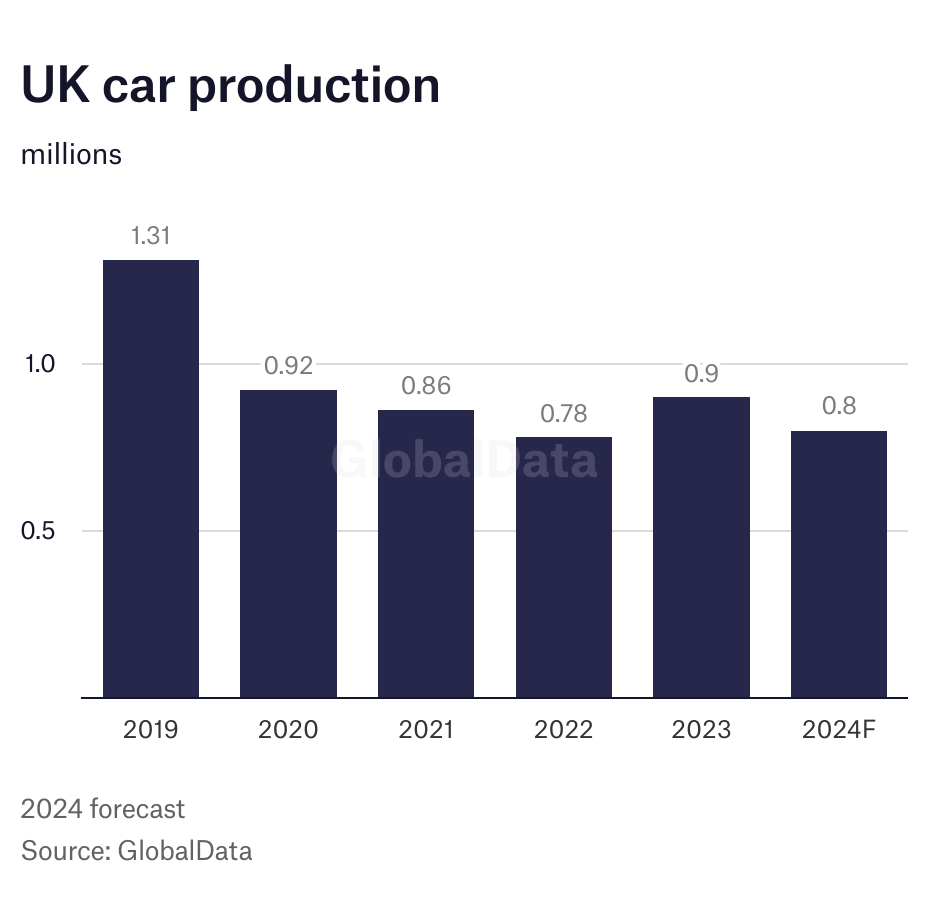

Justin Cox, an analyst at GlobalData, points out that although the January data is welcome, the UK’s auto industry has been hit by structural changes to output plans by some manufacturers.

“Besides the impact of the pandemic and subsequent supply shortages caused by the chips shortage, overall UK passenger car production has been hard hit by structural issues such as the closure of Honda’s Swindon plant and the loss of Vauxhall (Stellantis) Astra production from the Ellesmere Port plant in northwest England,” he says. In 2018, the Honda Swindon plant built some 160,000 cars (mainly Civic, but some CR-Vs) and Vauxhall (Stellantis) turned out over 77,000 Astras.

“And Jaguar Land Rover has moved Discovery and Defender manufacturing from the UK to its plant in Slovakia,” he adds.

“Our forecast for this year sees UK car output at around 0.8 million units. It was much higher before the pandemic, but we see it settling in the medium term at around a million units a year.”

EV challenges ahead

In response to the January data Richard Peberdy, UK Head of Automotive for KPMG, drew attention to the challenge to get more private individuals to switch to electric cars. He said: “Electric vehicle demand is largely being driven by low benefit-in-kind tax and write-down allowances for businesses, including company car and salary sacrifice schemes for employees.

“But growing private sales of new EVs is proving challenging.

“The UK automotive industry is hoping that the Budget contains measures to incentivise consumer EV purchasing, whilst also hoping for further measures to attract inward investment and boost the UK car industry’s competitiveness.”