Nissan is working with Altilium to recycle materials from used EV batteries.

The deal was part of a GBP30m collaborative project for which the Advanced Propulsion Centre (APC) had been awarded grant funding of GBP15m.

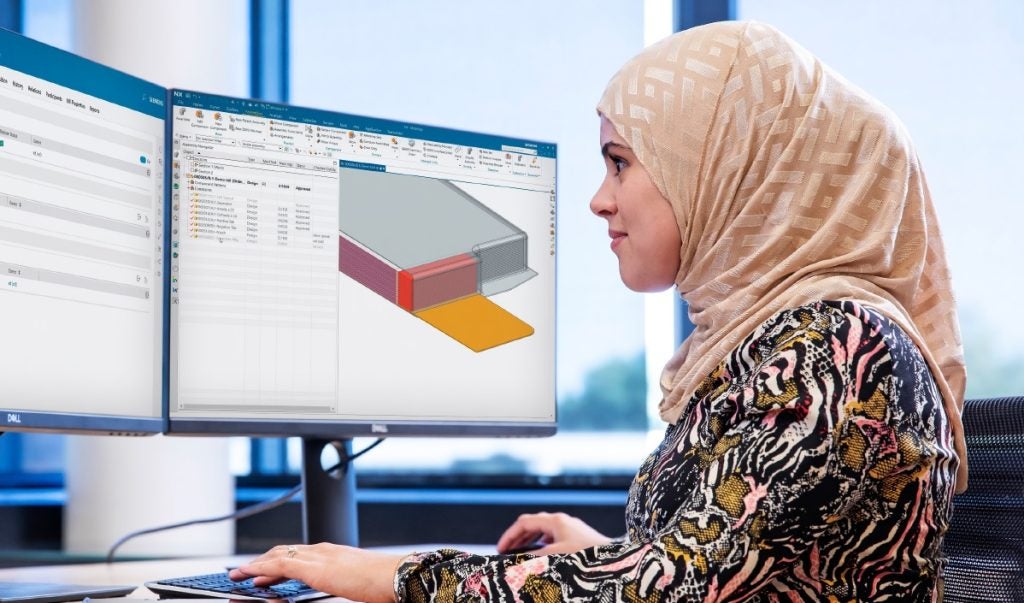

The programme would boost technical expertise and R&D at Nissan’s Technical Centre Europe (NTCE) in Cranfield, Bedfordshire, focusing on battery reuse, recycling and energy balancing.

The consortium also included Nissan battery producer AESC and Connected Energy whick supplies second life energy storage systems in the UK.

The goal was to maximise raw material recycling and develop a closed loop model for battery materials, reducing the need for mining. This would include processing waste from spent Nissan Leaf batteries and production scrap and using recovered materials to produce high nickel chemistry cathode active materials (CAM) for testing for future EV batteries.

Altilium claims its EcoCathode hydrometallurgical process can recover 95% of the cathode metals, including lithium, from end of life EV batteries.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe target is to halve CAM carbon footprint and reduce cost 20% compared to freshly mined materials.

The subsidy will enable Altilium to accelerate recycling facilities including the planned construction of an “industrial scale” centre on Teesside.

The company expects to produce 30,000 tonnes of battery ready CAM, enough to meet 20% of UK need, by 2030.